Blog

A-Z of Wood Flooring Jargon: Wood Flooring Terms

A-Z of Wood Flooring Jargon: Wood Flooring Terms

When you first start learning about wood flooring, you’ll hear terms like grain, knots, parquet, and t-moulding that are strange and extremely specialised to this sector.

Even if you have the assistance of a wood flooring professional, it’s necessary to have a basic awareness of the terminology used when discussing wood flooring so that you can fully participate in the process of selecting the perfect wood floor and ensuring that it is installed correctly.

Here are some of the more often used wood flooring terminology, along with definitions…

Acclimatisation

This is the process of enabling your wood flooring to acclimate to its new surroundings gradually before installing it. Because wood expands and contracts in response to changes in temperature and moisture levels, you should allow it to sit in the area where it will be installed for 3-7 days (depending on whether it is solid wood or engineered wood) before installing it.

Beading

This is a strip of wood that is used to conceal expansion gaps around the edge of the room where your wood flooring is installed. It is essentially an accessory. They’re also known as floor edge trims, and they come in a variety of materials.

Chevron

Chevron is a type of parquet flooring pattern.

It has a v-shaped form with a regulated zigzag pattern created by the wood planks meeting at a sharp point.

The flow of the directional design makes small and narrow areas feel much larger, and its elegant appearance naturally lends itself to Scandinavian style interiors.

Here’s where you can learn more about chevron and parquet wood flooring.

This Trade Price Bespoke Chevron Flooring comes if 6 basic colours Plus unfinished

Crowning

This is a problem with wood flooring where the centre of the board is high and the sides of the plank dip down.

It can be produced by a variety of factors, including moisture that causes the floorboards to swell and push against one another, or sanding a cupped floor.

Cupping

The flooring dips down in the middle of the plank and bends upwards at the borders, which is the opposite of crowning. The most common reason is moisture exposure, which causes the floor to expand and change form.

Distressed

Distressed wood flooring is made from wood that has been scraped or smashed by hand or machine to add character and make it appear older and worn.

It’s ideal for individuals who adore the look of antiques and want their home to have a more rustic and traditional feel.

Engineered Wood

Engineered wood flooring is made up of various layers of wood: a genuine hardwood surface layer and a plywood or three-ply block structure for the foundation layer.

It’s less expensive than solid wood and can be more durable.

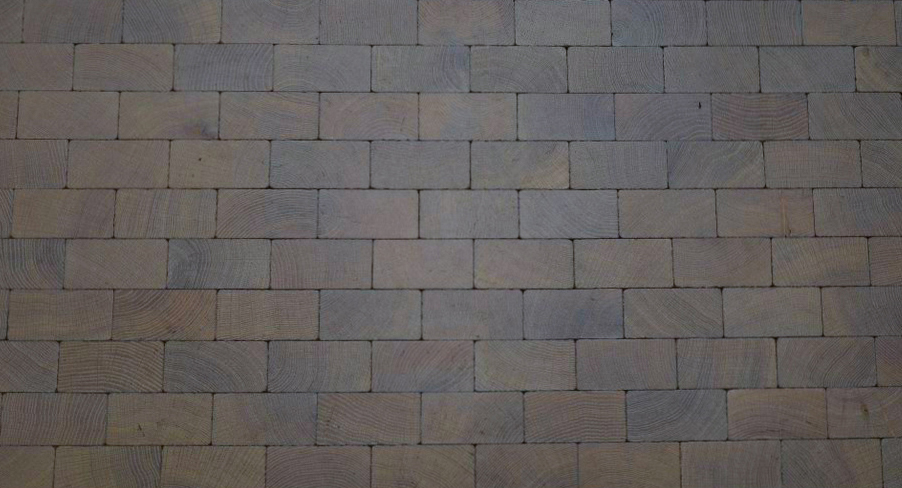

End Grain

End grain are square blocks cut across the grain, as if you are looking at the rings of a tree rather than normal flooring that is cut as long length looking at the grain from the side. Basically, small squares of blocks. End grains are very hard wearing and in the past cobbled streets often used end grain blocks instead of stone for the surface.

End grain , oak, brick pattern, finished in a white oil

Finish

The protective coating placed to the floor is referred to as the finish of wood flooring, and it can range from matte to high gloss to lacquer and oil.

Finish is applied after a floor has been sanded down as part of the refinishing process. New wood floors are normally pre-finished (the finish is applied before installation), but it is also applied after a floor has been sanded down as part of the refinishing process. It not only protects the wood, but it also provides aesthetic advantages.

Floating

The tongue and groove or click method used in floating wood flooring prevents the planks of wood from being attached directly to the floor, instead relying on the weight of the floor to keep them in place.

Grain

The grain refers to the visible lines and patterns on the surface of the boards, which represent the arrangement of the wood fibres for that species/type of wood.

More recognisable grains perform well in rustic and traditional interiors, whilst less obvious grains work best in contemporary designs.

Herringbone

In parquetry, a herringbone pattern is a sort of pattern.

It’s one of the most popular wood flooring styles, and it’s made of basic rectangular blocks laid together in a zigzag pattern to produce a mosaic effect that looks like fishbones, hence the name.

Oak, Herringbone, oil, smoked, blocks , tumbled

Knots

Knots are a round or oval form with a black outline that develop naturally in wood as a branch sprouts out of the main trunk. Although they are sometimes mistaken for flaws in the wood, they really accentuate the natural look and character of the flooring, which is ideal if you want to achieve a country-style, shabby chic impression.

Lacquered

Lacquered wood flooring has been treated with a resin that looks like varnish and gives it a glossy sheen.

Laminate

A multi-layer synthetic flooring product is laminate wood flooring. The top layer is a printed picture that has been covered with a transparent protective coating to give it the impression of wood flooring. HDF is used to construct the product’s core.

Parquet

Parquet flooring is made from wood planks set out in a regular or geometric pattern, the most common of which are chevron and herringbone.

Rustic

The term “rustic” refers to the look of wood because of its condition or preparation.

This sort of wood has natural beauty, increased blemishes, and is frequently recovered or repurposed, making it ideal for country-style houses and cottages.

Sanding

When repairing old or damaged flooring, this is the procedure of utilising an abrasive instrument on the wood. It eliminates the top layer of wood and leaves a smooth surface, giving the floor a whole new appearance.

Sheen Level

The sheen level of your flooring relates to how shiny it appears and is divided into four categories: matte (the least shining), satin, semi-gloss, and glossy (being the shiniest). The sheen level of your wood flooring will affect how simple they are to maintain, how much extra light the space receives, and even how long they will last.

Skirting

Skirting is a wooden board that runs down the bottom of a room’s walls to cover the gap between the wall and the floor and make the two appear more seamless.

It’s mostly used as a decorative element in interiors, like architrave.

Staining

This is the procedure of putting oil to the top layer of wood floors to finish them. This successfully dyes the wood to match the colour and feel of a certain area. It’s merely decorative and provides little to no further protection.

Subfloor

The subfloor, which is commonly built of wood or concrete, serves as the basis for the underlay and surface levels of flooring. It creates a firm and level platform on which new wood flooring may be swiftly and simply laid.

T-Moulding

A wood moulding that connects two wood floors or neighbouring rooms with the same height flooring. It is not to be confused with beading and is commonly installed at entrances.

Tongue and Groove is a phrase that means “tongue and groove.”

This is a basic way of installing wood flooring that involves fitting one plank’s protruding edge (the tongue) into a groove on the subsequent board. It’s the old-fashioned alternative to the click-fit system.

Underlay

Underlay is a thin layer of padding that lays beneath your wood flooring and acts as a barrier between the subfloor and the planks of wood.

It is constructed of sponge rubber, foam, felt, or recycled plastic and serves to offer sound, moisture, and heat insulation.

Unfinished

This refers to wood flooring that has not been treated with oil, lacquer, or brushing, and hence has no finish.

When a consumer wishes to use their own oil to stain the flooring after it has been put, this sort of wood is frequently chosen.

Layers to Wear

The wear layer of engineered or laminate wood flooring is the top layer. It normally gives your wood flooring more resilience, scratch, and stain resistance, and helps to keep its beauty for longer.

Whitewashed

This is when wood flooring has been sanded down and stained in a white colour to brighten the space and add to houses with a shabby-chic, beachy vibe.